Hooke’s Law:

It

states that when the material is loaded within the elastic limit, the stress is

directly proportional to the strain .i.e, the ratio of stress to the

corresponding strain is a constant within the elastic limit and the constant is

known as Young’s Modulus or Modulus of Elasticity.

Therefore

Stress α strain

Stress = E (strain)

E= stress/strain

E=σ/e

Where

E= Young’s Modulus σ =

stress of the material , e = strain in the material

Step1: Data:

Step1: Data

Step2: Calculation of area of the material

Step 3: Calculation of intensity of stress

Step 3:Calculation of intensity of stress

11) A hollow steel column of external diameter 250mm has to support an axial load of 2000KN.If the ultimate stress for the steel column is 480N/mm2.Find the internal diameter of the column allowing the factor of safety of 4.

Step 4 : Calculation of internal diameter of material

Step 1: case 1: solid bar

Step 3: Calculation of intensity of load

Step 4: Case 2: Hallow bar

Step 5: Calculation of area of material

Step 2: Calculation of intensity of stress

Step 3: Calculation of strain

Step5: Yield point stress

Step6: Ultimate stress

Step 8: percentage reduction in area

Step4: Calculation of intensity of stress

Step5: Calculation of intensity of load

Step 2 : Calculation of Working stress

Step 3: Calculation of internal diameter

Step 1: Data:

Step 6 : Calculation of thickness

Step 2: Calculation of intensity of stress

Step 3: Calculation of strain

Step5: proportionality limit stress

Step6: True breaking stress

Step 8: percentage reduction in area

PROBLEMS

ON STRESS, STRAIN AND YOUNG’S MODULUS

1) An elastic rod of 25mm in diameter ,200mm long

extends by 0.25mm under a tensile load of 40 KN. Find the intensity of stress,

strain and elastic modulus of the material.

Step1: Data

Length of the rod=200mm

Diameter of the rod=25mm

Extension =0.25mm

Load=40KN=40x103N

Step 2: Calculation of area of the material

A= πd2/4

= π (25)2/4

= 490.87mm2

Step 3: Calculation of intensity of stress

σ = load applied/ area of material

= 40x103/490.87

= 81.48N/mm2

Step 4: Calculation of strain

e = extension of rod /original length

= 0.25/200

= 1.25x10-3

2) A cast iron column has the external diameter of 300mm

and 20mm thick. Find the safe compressive load on the column with factor of

safety of 5, if the crushing strength of the material is 550N/mm2.

Step1: Data

External diameter = 300mm

Thickness = 20mm

FOS = 5

Crushing strength = 550N/mm2

Step2: Calculation of internal diameter

Internal diameter = External diameter + 2(thickness)

300+2(20)

340 mm

Step3: Calculation of area of the material

A= π (D-d) 2/4

= π (340-300)2/4

= 1256.64 mm2

Step 4: Calculation of safe stress

FOS = Ultimate stress/safe stress

5 = 550/ safe stress

Safe stress = 550/ 5

Safe stress = 110 N/mm2

Step 5: Calculation of Safe Load

Safe stress = Safe load /Area of cross section

110 =

Safe load/1256.64

Safe load = 138.230KN

3) A 30 mm diameter steel rod when subjected to an

axial force was subjected to a strain of 0.6x10-3. Find the tensile

force caused by the above strain. Take E=200KN/mm2

Step1: Data

Diameter =30 mm

Strain = 0.6x10-3

Young’s modulus E=200KN/mm2 = 2X105 N/mm2

Step2: Calculation of area of the material

A= πd2/4

= π (30)2/4

= 706.86 mm2

Step 3: Calculation of intensity of stress

E= σ/e

2X105= σ/0.6x10-3

σ = 120 N/mm2

Step 4: Calculation of Load

Stress = Load /Area of cross section

120 = Load/706.86

Load = 84.82KN

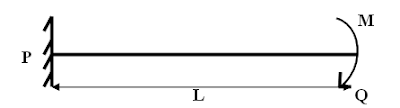

4) Find the maximum and minimum stresses

produced in thestepped bar as shown in the fig

due to an axially applied compressive load of 12KN.

Step1: Data

Compressive load=12 X 103N.

Minimum diameter = 12mm

Maximum diameter = 25mm

Step2: Calculation of area of the material

Minimum area= A= πd2/4

= π (12)2/4

= 113.09mm2

Maximum area =A = πd2/4

= π (25)2/4

= 490.87mm2

Step 3: Calculation of intensity of stress

Maximum stress: = Load / Minimum Area of cross section

= 12X1000/113.09

=106.11 N/mm2

Minimum stress: = Load / Maximum Area of cross section

= 12X1000/490.87

=24.45 N/mm2

Step1: Data

Diameter =3 mm

Load=495 N

Extension=0.07mm

Gauge length=100mm

Step2: Calculation of area of the material

A= πd2/4

= π (3)2/4

= 7.068mm2

Step 3: Calculation of intensity of stress

Stress = Load /Area of cross section

= 495/7.068

Stress = 70.03 N/mm2

Step 4: Calculation of strain

Strain = Extension/gauge length

= 0.07/100

= 0.7X10-3

Step5: Calculation of Young’s modulus

E = σ/e

= 70.03/0.7X10-3

=

1.00X104 N/mm2

6) A wooden tie is 75mm wide,150mm deep and 1.5m long.It is

subjected to a axial pull of 45000N.The stretch of the member is found to be

0.6380 mm. Find the Young’s modulus for the material.

Step1: Data

Width (b) =75mm

Depth (d) =150mm

Length(L) =1.50m=1.5X1000

Load = 45000N

Stretch = 0.6380mm

E =?

Step2: Calculation of area of the material

A= bXd

=75X150

=11.25X103 mm2

Step 3: Calculation of intensity of stress

Stress = Load /Area of cross section

= 45000/11.25X103

Stress = 4 N/mm2

Step 4: Calculation of strain

Strain = Stretch / length

=

0.6380/100

= 0.7X10-3

Step5: Calculation of Young’s modulus

E = σ/e

= 4/0.7X10-3

= 5.71X103N/mm2

7) A load of 4000N has to be raised at the end

of the steel wire. If the unit stress in the wire must not exceed 80N/mm2 what

is the minimum diameter required? What will be the extension of 3.5 m length of

wire? Take E=2x105N/mm2

Step1: Data:

Length(L) =3.50m=3.5X1000mm

Load = 4000N

Stress = 80N/mm2

E=2x105N/mm2

Minimum diameter=??

Extension=??

Step2: Calculation of area of the material

Stress = Load /Area of cross section

80 = 4000/Area of cross section

Area of cross section = 50mm2

Step3: Calculation of Minimum diameter

of material

A= πd2/4

50 = π(d)2/4

d = 7.978mm

Step 4: Calculation of strain

E = σ/e

2x105 = 80/e

e = 0.4X10-3

Step5: Calculation of Extension

of material

Strain = Extension/gauge length

0.4X10-3 = Extension/3.5X1000

Extension= 1.4mm

8) A wooden tie is 60 mm wide ,120 mm deep and 1.5 m long.It is

subjected to a axial pull of 30KN. The stretch of the member is found to be

0.625 mm. Find the Young’s modulus of the tie material.

Step1: Data

Width (b) =60 mm

Depth (d) =120 mm

Length(L) =1.50m=1.5X1000

Load = 30000N

Stretch = 0.6250 mm

E =?

Step2: Calculation of area of the material

A= bXd

=60X120

=7.2X103 mm2

Step 3: Calculation of intensity of stress

Stress = Load /Area of cross section

= 30000/7.2X103

Stress = 4.166 N/mm2

Step 4: Calculation of strain

Strain = Stretch / length

= 0.625/1.5X1000

= 0.416X10-3

Step5: Calculation of Young’s modulus

E = σ/e

= 4.166/0.416X10-3

= 1.00X104 N/mm2

9) A 20mm diameter brass rod was subjected to the tensile load

of 40KN. The extension of the rod was found to be 254 divisions in the 200mm

extensometer. If each division is equal to 0.001mm, find the elastic modulus of

the brass.

Step 1: Data

Diameter =20 mm

Tensile load = 40KN=40X1000

Gauge length =200 mm

No of divisions = 254

least count = 0.001mm

Extension = 254X0.001 = 0.254 mm

Step2: Calculation of area of the material

A= πd2/4

= π (20)2/4

= 314.16 mm2

Step 3: Calculation of intensity of stress

Stress = Load /Area of cross section

= 40000/314.16

Stress = 127.32 N/mm2

Step 4: Calculation of strain

Strain = Stretch / length

=

0.254/200

= 1.27X10-3

Step5:Calculation of Young’s modulus

E = σ/e

= 127.32/ 1.27X10-3

= 1.00X105 N/mm2

10) A hollow steel column has an external diameter of 250mm and

an internal diameter of 200mm. Find the safe axial compressive load for the

column if the safe compressive stress is 120N/mm2.

Step 1: Data

External diameter = 250mm

Internal diameter = 200mm.

Safe Compressive stress = 120N/mm2

Step2: Calculation of area of the material

A= π(D-d)2/4

= π (250-200)2/4

= 1963.49 mm2

Step 3:Calculation of intensity of stress

Safe Stress = Safe Load /Area of cross section

120 = Safe Load/1963.49

Safe Load = 235.61 KN

11) A hollow steel column of external diameter 250mm has to support an axial load of 2000KN.If the ultimate stress for the steel column is 480N/mm2.Find the internal diameter of the column allowing the factor of safety of 4.

Step 1: Data

External diameter = 250mm

Ultimate stress = 480N/mm2

Axial load = 2000KN

Factor of safety = 4.

Internal diameter = ?

Step 2: Calculation of working Stress

FOS=Ultimate stress /working stress

4 = 480/working stress

working stress= 120N/mm2.

Step 3: Calculation of area of the material

Stress = Load /Area of cross section

120 = 2000X1000/Area of cross section

Area of cross section = 16.66X103mm2

Step 4 : Calculation of internal diameter of material

A= π(D-d)2/4

16.66X103= π (250-d)2/4

d= 104.35 mm

12) A solid alloy bar of 40mm in diameter is used as a tie. If

the permissible tensile stress in the material is 320N/m2, determine

the capacity of the bar. If the hollow steel bar with internal diameter of 20mm

is used instead of solid alloy bar determine its external diameter. For steel

hollow bar the permissible stress is 150N/mm2.

Step 1: case 1: solid bar

Diameter = 40mm

stress = 320N/mm2

Step 2: Calculation of area of material

A= πd2/4

= π (40)2/4

=1256.63mm2

Step 3: Calculation of intensity of load

Stress = Load /Area of cross section

320 =Load/1256.63

Load = 402.12KN

Step 4: Case 2: Hallow bar

internal diameter: 20mm

stress = 150N/mm2

Step 5: Calculation of area of material

Stress = Load /Area of cross section

150= 402.12X1000/Area of cross section

Area of cross section=2680.8mm2

A= π(D-d)2/4

2680.8= π (D-20)2/4

D

= 38.42mm

13) Fig shows a steel wire and a copper wire

of each of length 1m and carrying an axial load of 5KN.

a) For

the same diameter of the wires find the ratio of extension of the copper wire

to the extension of the steel wire.

b) For

the same extension of the wires ,find the ratio of the diameter of the copper

wire to the diameter of the steel wire .TakeEs=2x105N/mm2

and Ec=1.2x105N/mm2

Step 1: For the same diameter of the wires

we know that E = σ/e

Given Es=2x105N/mm2 and E c=1.2x105N/mm2

Therefore, Es/E c=

(Extension of steel)/ (Extension of copper)

(Extension of steel)/ (Extension of copper) = (2x105) /(1.2x105)

= 1.67

Step 2 : For the same extension of the wires

Es/E c=Ac/As

Es/E c=(dc/ds)2

dc/ds = 1.29

ds/dc=0.774

14) The

following data refer to a mild steel specimen tested in laboratory:

a) Diameter of the specimen=25mm

b) Length of the specimen=300mm

c) Extension under a load of

15KN=0.045mm

d) Load at yield point=127.65KN

e) Maximum load=208.6KN

f) Length of the specimen after

failure= 375mm

g) Neck diameter=17.75mm

Determine young’s modulus, yield point, ultimate stress, percentage elongation,

percentage reduction in area, safe stress with FOS of 2.

step 1: Calculation of area of material

A= πd2/4

= π (25)2/4

=490.87mm2

Step 2: Calculation of intensity of stress

Stress = Load /Area of cross section

=15X1000/490.87

Stress = 30.55N/mm2

Step 3: Calculation of strain

Strain = Stretch / length

=

0.045/300

= 0.15X10-3

Step4: Calculation of Young’s modulus

E = σ/e

= 30.55/0.15X10-3

= 2.03X105 N/mm2

Step5: Yield point stress

Stress = Load /Area of cross section

=127.65X1000/490.87

Stress = 260.04N/mm2

Step6: Ultimate stress

Stress = Load /Area of cross section

=208.6X1000/490.87

Stress = 424.96N/mm2

Step 7: percentage elongation

percentage elongation = {(length at failure-initial length)/length at

failure)}X100

=

{(375-200)/375}X 100

= 46.67%

Step 8: percentage reduction in area

final area=A= πd2/4

= π (17.75)2/4

=247.44mm2

percentage reduction in area= {(initial area-final area)/initial area}

X100

= {490.87-247.44)/490.87}X100

= 49.59%

14) A bar of diameter 20 mm and length 100 mm extends by 0.2 mm.

If E of the material is 2x105N/mm2, what amount of load

applied to the rod. If an extension of 20% greater is required for the same

load applied above, how much the diameter of the bar need to be reduced.

Step 1: Data:

case 1:

Diameter = 20 mm

Length = 100 mm

Extension = 0.2 mm

E= 2x105N/mm2

Load =??

Step 2: Calculation

of area of material:

A= πd2/4

= π (20)2/4

= 314.16 mm2

Step 3: Calculation of strain

Strain = Extension / length

=

0.2/100

= 2X10-3

Step4: Calculation of intensity of stress

E = σ/e

2x105 = σ / 2X10-3

σ =400N/mm2

Step5: Calculation of intensity of load

Stress = Load /Area of cross section

400 =Load/314.16

Load = 125.66KN

Step6: Case 2

Extension is 20% more:

Total extension =1.2X0.2 = 0.24mm

Load = 125.66KN

Diameter = d =??

Length = 100 mm

Step 7: Calculation of strain

Strain = Extension / length

= 0.24/100

Strain = 2.4X10-3

Step8: Calculation of intensity of stress

E = σ/e

2x105 = σ / 2.4X10-3

σ = 480N/mm2

Step9: Calculation of diameter

Stress = Load /Area of cross section

480 =125.66X1000/A

A =261.79 mm2

261.79 =

πd2/4

= π(d)2/4

d = 18.25 mm

Step 10 : percentage reduction in diameter

(initial diameter-final diameter)/initial diameterX100

{(20-18.25)/20} X 100

= 8.75%

15) A

short piece of steel pipe is to carry a compressive load of 1000KN with a

factor of safety of 2 against yielding. If the thickness of the pipe is to 1/5th of

the outside diameter, Find the minimum required outside diameter Take yield

stress of the steel as 280MPa.

Step 1: Data:

Load = 1000KN

Factor of safety = 2

Outside diameter = D

Thickness = 1/5th D

yield stress = 280MPa = 280N/mm2

Step 2 : Calculation of Working stress

FOS= yield stress /working stress

2 = 280/working stress

Working stress= 140N/mm2.

Step 3: Calculation of internal diameter

d = D-2t

d = D-2(1/5) D

d = 0.4D

Step4: Calculation of intensity of stress

Stress = Load /Area

of cross section

140 =1000X1000/A

A

=7142.85 mm2

Step 5:

Calculation of diameters

A= π(D-d)2/4

7142.85= π (D-0.4D)2/4

D = 119.2 mm

d = 71.52 mm

16) A hollow steel tube

is used to carry a compressive load of 150KN. The yield stress for steel is

250N/mm2 and factor of safety is 2 determine the thickness of

the steel specimen if the external diameter is 100mm.

Step 1: Data:

Load = 150KN

yield stress

= 250N/mm2

factor of safety = 2

external diameter =

100 mm.

Step 2:

Calculation of Working stress

FOS= yield stress /working stress

2 = 250/working stress

Working stress=

125 N/mm2.

Step3:

Calculation of intensity of stress

Stress = Load /Area

of cross section

125 =150X1000/A

A =1200 mm2

Step 5: Calculation

of diameters

A= π(D-d)2/4

1200= π (100-d)2/4

d = 60.91 mm

Step 6 : Calculation of thickness

t = {(D-d)}/2

t = {(100- 60.91)}/2

t = 19.54 mm

17) The

tensile test was conducted on a mild steel bar. The following details are

a) Diameter

of the steel bar=16mm

b) Load

at proportionality limit= 72KN

c) Load

at failure=80KN

d) Diameter

of the rod at failure=12mm

e) Gauge

length of the bar =80mm

f) Extension

at the load of 60KN=0.115mm

g) Final

length of the bar=104mm

Determine young’s modulus,

proportionality limit stress, true breaking stress, percentage elongation of

the material.

step 1: Calculation of area of material

A= πd2/4

= π (16)2/4

=201.06 mm2

Step 2: Calculation of intensity of stress

Stress = Load /Area of cross section

=60 X1000/201.06

Stress = 298.41N/mm2

Step 3: Calculation of strain

Strain = Stretch / length

= 0.115/80

= 1.43X10-3

Step4: Calculation of Young’s modulus

E = σ/e

= 298.41/1.43X10-3

= 2.07X105 N/mm2

Step5: proportionality limit stress

Stress = Load /Area of cross section

=72X1000/201.06

Stress = 358.10N/mm2

Step6: True breaking stress

Stress = Load /Area of cross section

=80X1000/201.06

Stress = 397.89N/mm2

Step 7: percentage elongation

percentage elongation = {(length at failure-initial length)/length at

failure)}X100

= {(104-80)/104}X

100

=23.07%

Step 8: percentage reduction in area

final area=A= πd2/4

= π (12)2/4

=113.09mm2

percentage reduction in area= {(initial area-final area)/initial area}

X100

= {201.06-113.09)/201.06}X100

= 43.75%

Thanks for sharing this useful information. I am collecting more details about Tensile Testing Machine Manufacturer If you have relevant data then kindly keep sharing.

ReplyDeleteThanks for this. I really like what you've posted here and wish you the best of luck with this blog and thanks for sharing. EXTC

ReplyDeleteThis test is nice but i will add strain gauge formula inforamtions

ReplyDeleteVery significant Information for us, I have think the representation of this Information is actually superb one. This is my first visit to your site. Eilat lev equipment

ReplyDeleteWow what a great blog, i really enjoyed reading this, good luck in your work. Clyde hollick

ReplyDelete